Hydraulic Core Drilling Machine

Powerful Christensen Head – High-torque through-hole chuck efficiently manages 3 m drill rods with ease.

Intelligent Hydraulic System – Pilot-controlled constant-pressure drilling ensures precise, smooth, and stable performance.

Sliding Feed Beam – Enables rapid positioning and enhances operational stability during drilling.

Telescopic Mast & Hydraulic Legs – Simplifies setup and positioning, providing flexibility for handling long drill rods.

Fast Rod Clamping – Nitrogen-assisted clamping system offers quick, reliable, and low-maintenance operation.

Optional Wireless Crawler – Allows remote control for safe and flexible maneuvering across challenging terrain.

Product Introduction

The CX1000 Core Drilling Machine is engineered for a wide range of exploration projects, combining high productivity with excellent maneuverability. It features a sliding box-type feed beam, hydraulic leveling jacks, and an extendable mast, allowing quick and accurate rig positioning in diverse working conditions.

A wireless remote-controlled crawler system enhances adaptability across various terrains, enabling safe-distance operation and minimizing operator risk. In addition, standard safety warnings and emergency stop systems ensure superior safety and reliability during drilling operations.

With its advanced structure and intelligent control, the CX1000 delivers efficient, flexible, and secure surface core drilling performance, making it an optimal solution for modern geological exploration.

Product Details

Product Specifications

Drilling Capacity | B / N / H: 880 / 780 / 480 m (CX800) |

B / N / H: 1060 / 960 / 560 m (CX1000) | |

Maximum Rod Size: P (114 mm) | |

Power Unit | Model: Cummins 4BT water-cooled diesel engine |

Power: 105 / 123 kW @ 1800–2200 RPM | |

Feed System | Stroke: 1.8 m |

Feed Force: 59 kN / 65 kN | |

Pull Force: 118 kN / 128 kN | |

Power Head | Drive Type: Variable hydraulic motor |

Max Torque: 2000 Nm / 2400 Nm | |

Wireline Winch | Rope Capacity: 800 m (ID 6 mm) |

Pulling Force: 11 kN | |

Rod Clamp | Through-hole Diameter: 120 mm |

Clamping Force: 5000 kg | |

Hydraulic System | Main Pump: 25–28 MPa, 112–135 L/min |

Auxiliary Pump: 21–25 MPa, 22–30 L/min | |

Third Pump: 15 MPa, 10 L/min | |

Crawler (Optional) | Drive Type: Hydraulic |

Track Type: Rubber Track | |

Control: Wireless Remote | |

Travel Speed: up to 3 km/h | |

Dimensions & Weight (Transport Mode) | L × W × H: 5150 × 2700 × 2340 mm |

Weight: 3600 kg | |

Optional Attachments | Hydraulic torque mixer |

Hydraulic mud pump: 160 L/min @ 7 MPa |

Application Scenarios

The CX1000 Hydraulic Core Drilling Machine is engineered for a wide range of geological and exploration drilling applications. It is perfectly suited for mineral exploration, geotechnical surveys, core sampling, and scientific drilling across challenging terrains. With its high-torque hydraulic power head, intelligent pressure control system, and telescopic mast, the CX1000 ensures efficient and precise coring for both surface and medium-depth drilling using 3-meter drill rods.

Equipped with a wireless remote-controlled crawler chassis and hydraulic leveling legs, the CX1000 offers superior mobility and adaptability on mountainous, plateau, and uneven ground conditions. This makes it an ideal choice for remote field exploration, providing exceptional stability, productivity, and safety during long-duration drilling operations.

Packaging & Shipping

The CX1000 Hydraulic Core Drilling Machine is designed with a compact structure and optimized layout, making transportation efficient and cost-effective. It can be easily loaded into standard 20ft or 40ft containers for overseas shipment or delivered locally by flatbed truck.

Featuring a foldable mast, detachable feed beam, and hydraulic crawler chassis, the rig allows for quick disassembly and reassembly, effectively reducing its transport height and footprint. This ensures safe handling and smooth logistics during long-distance or multi-site transfers.

For remote field operations, the CX1000 can self-propel via its crawler tracks or be towed by construction vehicles, enabling rapid site relocation and flexible deployment—ideal for dynamic exploration projects in varied and challenging terrains.

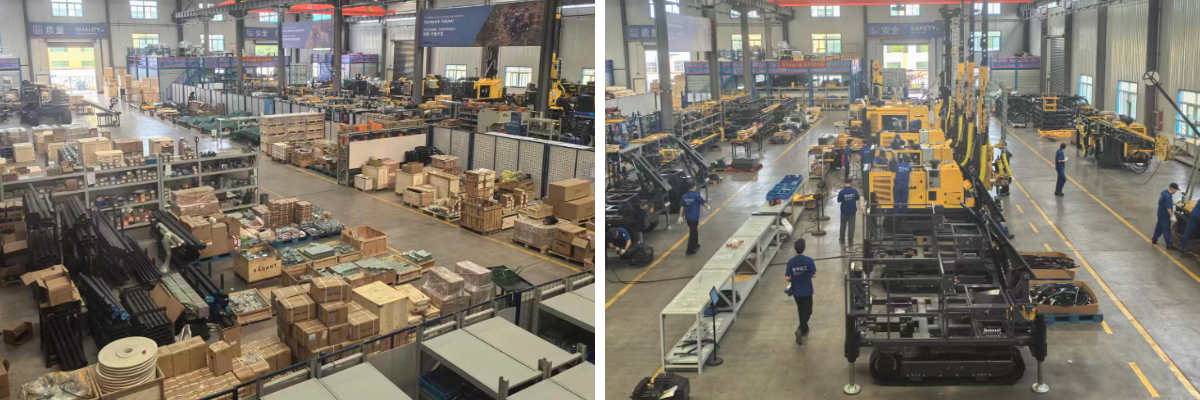

Company Strength

Puhua Energy Equipment Technology (Shandong) Co., Ltd., founded in 2003 in Jining, China, is a high-tech enterprise specializing in the design and manufacture of geological exploration, intelligent mining, and new energy equipment. Leveraging strong R&D capabilities and advanced production technology, Puhua provides high-efficiency drilling rigs, intelligent underground transportation systems, and tailored engineering solutions for mining projects worldwide.

The company collaborates with over 30 major mining enterprises, including Shandong Energy, Yintai Gold, and Shandong Gold, and has exported its products to more than 120 countries and regions. Supported by ISO9001 certification and a Canadian R&D center, Puhua’s equipment performs reliably under extreme working conditions—from mountainous regions to desert environments. With a reputation for innovation, precision, and reliability, Puhua has established itself as a global leader in the energy and mining equipment sector.